Build with Integrity: A Playbook for Luxurious, Responsible Materials

What Ethical Sourcing Means in High-End Construction

Navigating Certifications Without Losing Design Ambition

Traceability and Chain-of-Custody in a Global Supply Web

From Quarry to Facade: Documenting Stone

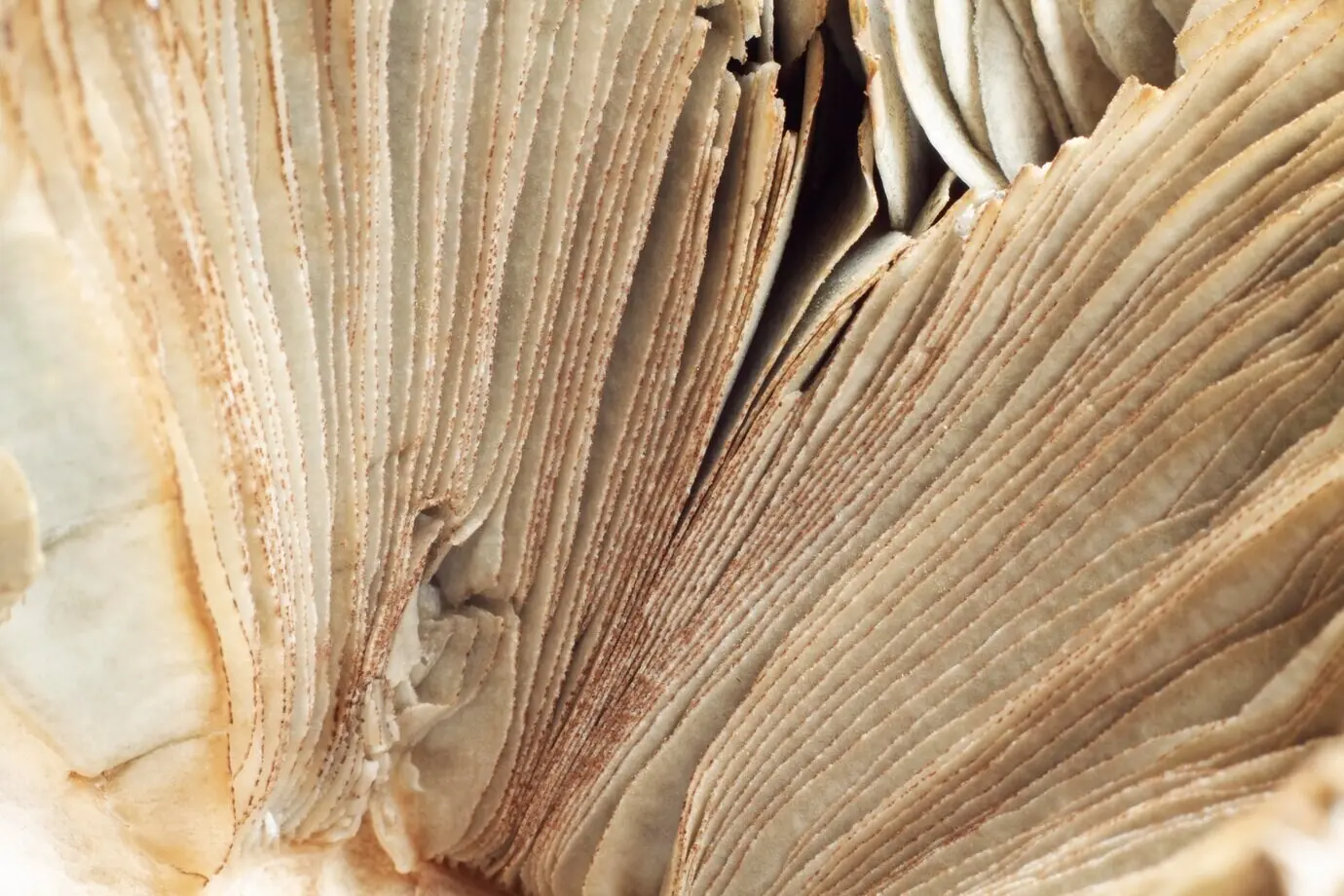

Stone procurement benefits from a traveler document accompanying each block. Record quarry coordinates, bench identification, and geological notes; add photos before and after resin treatments. At the fabricator, engrave batch IDs on edges hidden after installation. Reconcile slicing plans with delivered panel counts, waste percentages, and crate labels. Inspect protective film specifications, humidity controls, and impact sensors. These practical steps catch substitutions early, protecting aesthetics and ethics with the same vigilant attention.

Smart Tags and Digital Product Passports

Smart tags and QR codes can store batch identifiers, certificates, and transport events, enabling instant checks by site supervisors. Pair them with read-only data exports to satisfy owners’ cybersecurity policies. For bespoke millwork, embed discreet RFID in carcasses and reference material passports within O&M manuals. Over project life, future maintainers recover exact finishes and repair parts without guesswork, reducing waste while preserving the original vision with documented, traceable assurance.

Material Spotlights: Timber, Stone, Metals, and Low-Carbon Concrete

Engineered Timber with Provenance

Stone with Conscience and Enduring Beauty

Metals and Mineral Binders that Perform Responsibly

Procuring Responsibly: Contracts, Vetting, and Risk Management